Applications with thicker coverglass benefit from physical tempering such as outdoor entry systems, security communications and public signage systems where vandalism could occur. The outer surface of the glass cools more quickly than the centre, which has the effect of compressing the edges as the centre pulls away from it, increasing the tension of the glass and therefore the toughness. The second way of strengthening the glass is physical tempering, where the glass is slowly heated to around a peak temperature of 700☌ and then cooled rapidly by high pressure air. Chemically strengthened glass is the method seen in most applications including medical and automotive devices. Aluminosilicate glass also keeps its shape and doesn’t bend after chemical strengthening, unlike soda-lime glass where its curve allows it some room to flex if the glass is pressurised. After toughening, aluminosilicate glass has a typical strength of 600 megapascals (mpa) compared to soda-lime glass, which is generally in the region of 450 mpa. The larger surface ions are squeezed together to form a stress layer.

The sodium ions are replaced by larger potassium ions on the surface of the glass. Chemical strengthening involves soaking the glass in a KNO 3 solution at a temperature of 420☌. There are two ways that glass is normally strengthened, and each has its own pros and cons. Strengtheningīoth types of cover lens glass are strengthened before use. The main features that make aluminosilicate glass attractive for cover lens use are its resistance to high temperature and chemical exposure, and its ability to withstand scratching. Because of its cost, it is usually only found in higher-end and niche applications where additional strength and protection is paramount, such as smartphones and AR/AV devices. The main alternative to soda-lime glass is aluminosilicate glass, which offers better performance than its competitor, but is much harder to produce and therefore can be up to 6 times more expensive. As it is easy to manufacture, it is very affordable. As would be expected from its popularity, it offers a well-balanced list of specifications that includes good mechanical strength, optical parameters and temperature resistance. Soda-lime is the most well-known type of glass and makes up around 90% of the glass used in the world.

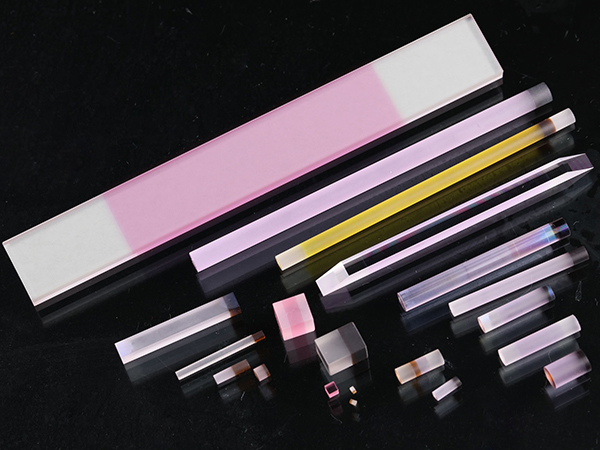

The two main types of glass used to manufacture cover lens each have their own properties and are used for different applications.

However, not all glass is equal and there are different treatments that can complicate the decision process. Cover lenses are usually fabricated from glass. LCD displays are very fragile and normally require a cover lens to be added in front of the display to protect it from damage and ensure that the data on display can be seen as clearly as possible. They can be produced in almost any size and shape to fit the required application and this flexibility allows them to be used in many different situations and environments. One of the most appealing things about LCD displays is their flexibility.

In some cases, they also allow us to control the application through touch. Displays provide the easiest method of viewing relevant and often complex information about the status of applications and equipment. Initially they were seen as an expensive luxury for top of the range products, but as manufacturing issues have been ironed out and new innovations have been made available to nullify some of their drawbacks, their performance has improved almost as fast as their price has dropped. Liquid crystal display (LCD) screens seem to be incorporated in almost every electronic product imaginable these days.

Liquid crystal display ion bonding how to#

Alexander Pang explains how to get the best out of your LCD with the right coverlens

0 kommentar(er)

0 kommentar(er)